We're here to help you get the most out of your CNC machine. We've spent over 10 years making CNC machines that are easy to use, and easy to learn.

#Cnc linear rail pro#

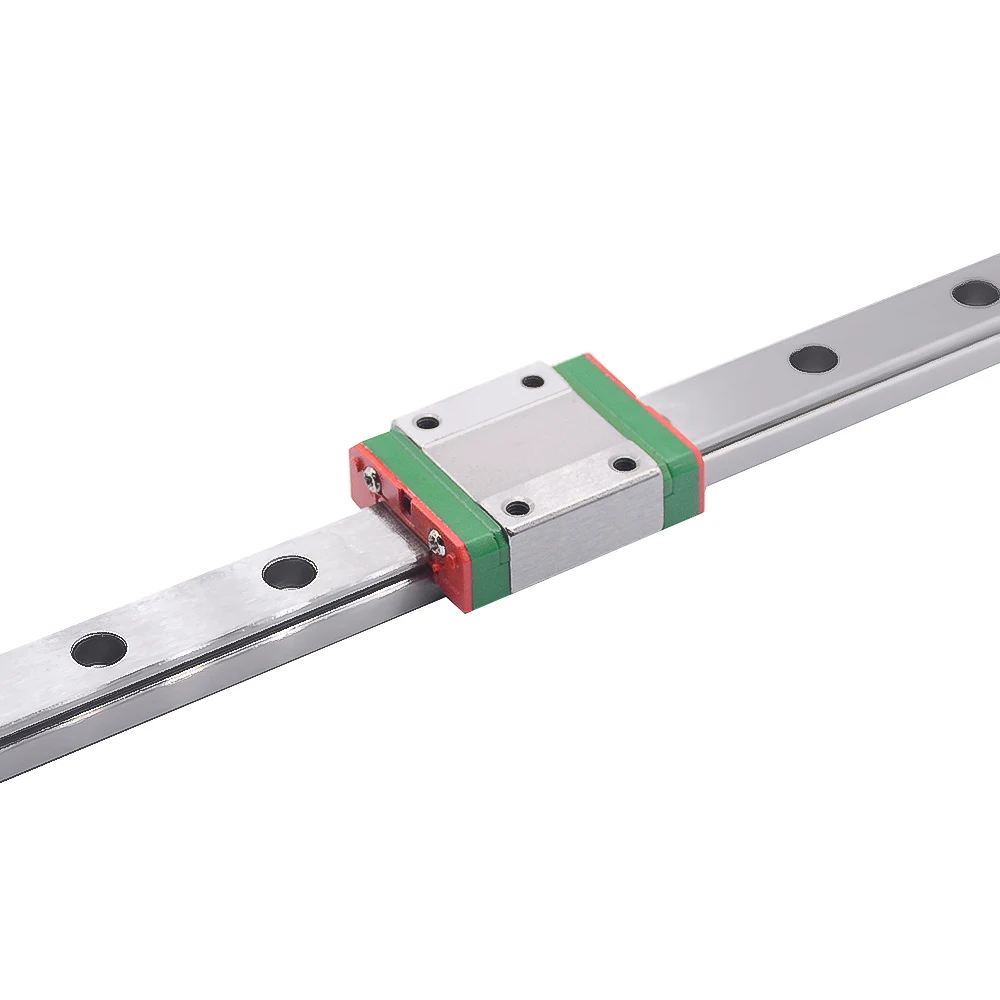

Shapeoko 5 Pro and Shapeoko HDM - Both use heavy-duty linear rails coupled with ball screws for maximum performance and rigidity.Ĭarbide 3D was founded by engineers and manufacturing people to make the CNC machines that we wanted. Linear bearings are more rigid and have higher performance than V-wheels, but they need to be wiped down and kept clean for the longest life. Shapeoko Pro - Shapeoko Pro uses linear bearings on every axis. They are less rigid than linear rails, but they’re a great blend of performance and value. Shapeoko 4 - Shapeoko 4 uses V-wheel rollers, which are inexpensive and durable. The motion system is the collection of slides that let the machine move, to the way to motors are connected to the various moving parts. Shapeoko HDM - Available with a cutting area of 27x21” Motion System Shapeoko 5 Pro - Available with cutting areas from 24x24" to 48x48” Shapeoko Pro - Available with cutting areas from 16x16” to 33x33” Shapeoko 4 - Available with cutting areas from 16x16” to 33x33”

The most visible characteristic of a CNC Router is the cutting area, and it’s very simple- the bigger the machine, the larger the parts you can cut. Workholding - Hybrid table (optional), Essential Clamps, and Teez-Nutz Cutting Size

#Cnc linear rail software#

Software - Carbide Create CAD/CAM software We’ve got plenty more to choose from to add capabilities to your router.

Don’t worry, we include them with all Shapeoko CNC Routers, which is why we're proud to be the best value in CNC routersĬutters - We include a #201 carbide endmill. To use it, you’ll need a lot of other components. What’s included?Ī CNC Router is just a part of a large system. They’re all just a little different, and some of those differences come down to preferences or subjective choices. The bit size is a very important consideration! Depending on your software, if the cutter is too large it will either over-cut the root and weaken the tooth, or leave a radius and not finish the involute profile or undercut.It’s tough to compare CNC routers directly. Pro-Tip! Notes for the wood shop or anyone using an endmill to make the cut: For measuring and inspecting gears, using a Measurement Over Pins Calculator is one of the best methods to ensure your gears are perfectly in-spec. So we put the same attention to detail and mathematical skill to work for everyone. We also see low resolution involute shapes that could function better if they had the correct geometry with sufficient data points defining the involute.īeing members of the American Gear Manufacturers Association (AGMA) and having manufactured gears in most plastics and metals, the details count. This can make gears bind or function poorly. One of the more common mistakes we see in simplified gear software is the lack of undercut in small tooth count gears. Gear 1 and Gear 2 can have the same or different center hole diameters.Ĭenter Distance – This is the distance between the two shaft centers holding the gears. Another way to think about it is positive profile shift numbers will allow for more backlash between two gears en-mesh.Ĭenter Hole Diameter – Central bore hole in each gear, for standard size we’d recommend the Machinery's Handbook. A positive profile shift represents a theoretical cutter cutting deeper (leaving longer, thinner teeth), while a negative shift would cutter more shallow (leaving shorter, thicker teeth). Profile Shift – Default is 0 for most applications. To convert, use: Module = 25.4 / Diametral Pitch Module (Pitch) – this parameter sets the tooth size. The rack length defaults to the diameter of Gear 2. Gear Type – External spur gears use a positive tooth count, while internal spur gears use a negative tooth count. Tooth Count – is set with the parameter "n" for Gear 1 and Gear 2

#Cnc linear rail free#

0 kommentar(er)

0 kommentar(er)